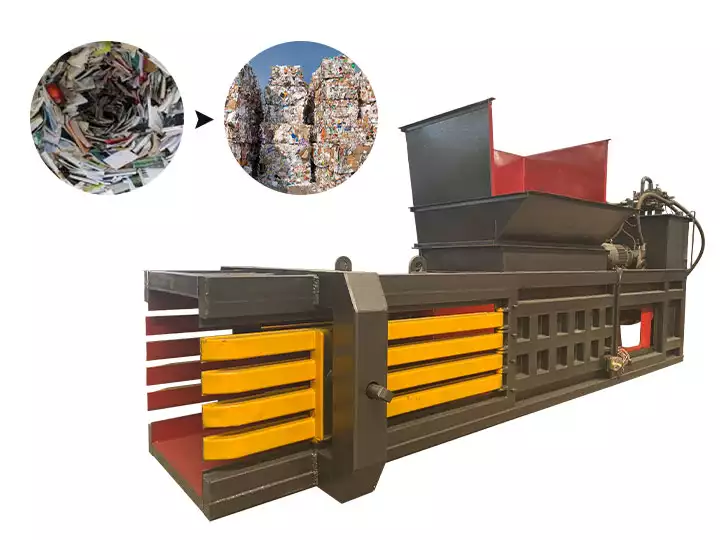

The horizontal baler machine that can squeeze many kinds of materials, like cardboard, textile, and plastic, into tight bales. The machine works by using a strong force to push materials together and make them smaller. This helps save money and make the environment cleaner by reducing the amount of waste.

Shuliy Machinery provides a series of horizontal waste balers for sale. The hydraulic power of the machine from 120 ton to 200 ton. What matter industry you are in, we can supply excellent horizontal bailing machine solutions for your specific needs, including fully automatic horizontal baler and semi automatic horizontal baler. Get in touch with us today to get best price.

What is a horizontal baler?

A horizontal baler is a machine used for compressing a wide range of materials into dense, compact bales. It is typically used for waste management and recycling purposes and is commonly used in industrial and commercial settings. The machine uses a hydraulic ram to press the materials together tightly, creating a smaller and more compact bale that can be easily stored or transported. By using a horizontal baler, businesses can save money on waste management and reduce their environmental impact.

Horizontal baler machine for sale

Shuliy is a well-known supplier of horizontal baler machines for sale. Their machines are designed to compress a variety of materials, including paper, cardboard, plastics, and textiles, into tightly compacted bales. Shuliy’s horizontal balers come in different models and specifications to meet different needs and budgets.

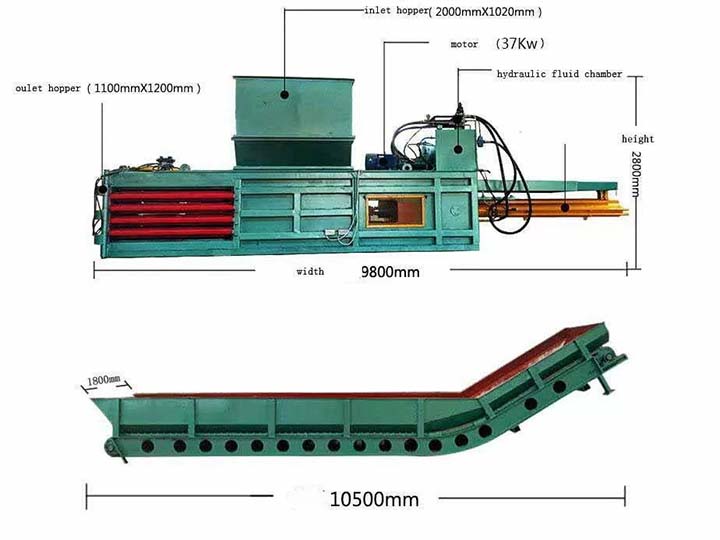

One of Shuliy’s popular horizontal baler machines for sale is the SL-160 model, which has a compression force of 160 tons and a bale size of 1100 x 1250mm. This machine is suitable for processing large volumes of materials and is easy to operate, with automatic bale ejection and wire tying functions. Overall, if you’re looking for a horizontal baler machine for sale, Shuliy is a trusted and reliable supplier that offers quality machines at competitive prices.

Features and benefits of a horizontal baler

1. Efficient Compression: Horizontal balers are designed to compress materials quickly and efficiently, resulting in dense bales that take up less space.

2. Versatility: Horizontal balers can compress a wide range of materials, including paper, cardboard, plastics, and textiles. This makes them suitable for a variety of industries, from manufacturing to retail.

3. Easy Operation: Most horizontal balers are easy to operate and require minimal training.

4. Improved Safety: Horizontal balers are designed with safety features that reduce the risk of accidents and injuries.

5. Environmental Benefits: By compressing materials into dense bales, horizontal balers help reduce the amount of waste that goes to landfills.

6. Cost Savings: Horizontal balers can help businesses save money on waste management and transportation costs.

Horizontal baler machine parameters

| Model | SL-120/100 | SL-180/160 | SL-200 | SL-220 |

| Pressure | 28Mpa | 28Mpa | 31.5Mpa | 31.5Mpa |

| Feeding port size | 1700*1020mm | 2000*1100mm | 1100*2000mm | 1100*2000mm |

| Final product size | 1100*900mm | 1100*1300mm | 1100*1300*1500mm(ajustable) | 1500*1100*1400mm |

| Final product weight | 1100-1550kg | 1100-1550kg | 1100-1550kg | 1100-1550kg |

| Total motor | 22kw | 43.5kw | 55kw | 62kw |

| Packing way | Manual tempered wire 2.8-3.2mm 3 lines | Automatic tempered wire 2.8-3.2mm 4 lines | Automatic12# wire 5lines | Automatic 12# wire 5 lines |

| Control system | PLC System | PLC System | PLC System | PLC System |

| Capacity | 7T/H | 10T/H | 12T/H | 14T/H |

| Oil type | 46# Hydraulic oil | 46# Hydraulic oil | 46# Hydraulic oil | 46# Hydraulic oil |

| Oil tank | 2000kg | 2000kg | 2000kg | 2000kg |

The machine equipped with PLC control system, make it easy operate and control. Besides, the capacity of the horizontal baler machine can be up to 14 ton per hour. And the oil type of the machine use 46# hydraulic oil. Furthermore, we offer strong customization service to meet all your specific requirements. Welcome to contact us to get a custom baling solution for your project.

How horizontal balers work?

Horizontal balers compress a wide range of materials, such as paper, cardboard, plastics, and textiles, into tightly compacted bales. The process involves loading the materials onto a feed conveyor, which then moves them into the compression chamber. The materials are compressed using a hydraulic ram, which applies pressure to the materials to create a dense bale. Once the materials have been compressed, the baler ties them off with twine or wire and ejects them from the machine, ready for storage or transportation.

Horizontal baler machine working video

How much does a horizontal baler cost?

The cost of a horizontal baler can vary depending on several factors such as its size, capacity, features, and supplier. Smaller horizontal balers may cost a few thousand dollars, while larger and higher-capacity balers are expensive. Automated features, such as bale tying and automatic ejection, can increase the cost. It’s important to consider ongoing costs such as maintenance, repairs, electricity, and labor. The investment in a horizontal baler can provide long-term cost savings and improve waste management and recycling efficiency. To get an accurate price, it’s best to consult with suppliers and compare prices and features to find the best option that suits your specific needs and budget.

What is the difference between horizontal and vertical balers?

Horizontal and vertical balers are both used to compress and package waste materials for recycling or disposal. The main difference between the two is the orientation of the machine during operation.

Horizontal balers compress waste materials from a horizontal position, with the waste being fed into the machine from the side. These machines are ideal for processing large volumes of waste materials, particularly bulky items such as cardboard boxes, plastics, and other recyclable materials.

Vertical balers., on the other hand, compress waste materials from a vertical position, with the waste being fed into the machine from the top. These machines are generally smaller and are best suited for processing smaller volumes of waste materials, such as plastic bottles, paper, and aluminum cans.

Factors to consider when choosing a horizontal baler

When choosing a horizontal baler, consider material type and volume, space availability, automation features, maintenance and support, and budget. Material type and volume are essential, while space availability determines the size of the baler. Automation features can increase productivity but may be expensive. Maintenance and support are critical for efficient operation. Choose a supplier that offers technical support, training, and spare parts. Budget is an essential factor, as balers vary in price depending on features and capabilities. By considering these factors carefully, you can select a horizontal baler that suits your needs and helps manage waste and recycling efficiently and sustainably.

When buying a horizontal baler machine, think about what kind of materials you have, how much space you have, and how much money you can spend. The Horizontal Baler is a good choice for managing waste and recycling materials.

We are a leading baler machine factory and supplier. Horizontal balers are one of our popular products. Besides, we have various vertical balers, metal balers, can balers, cardboard balers, plastic balers, etc. Welcome to contact us for the best quote today.