Metal briquette machine, also known as a metal briquetting machine or metal briquette press. It is a specialized equipment used to compress metal scraps into compact and dense briquettes for easier handling, transportation, and recycling. The metal briquette machine offers an effective solution for reducing the volume of metal waste and converting it into valuable resources.

This metal briquetting machine is suitable for pressing aluminum chips, copper chips, iron chips, mineral powder, etc. The density of scrap metal after briquetting is from 5 ~ 6 ton/m³. Besides, all machine from Shuliy factory use durable material and assured quality. And they enjoy 12 months warranty. If you want to start your metal recycling business, welcome to contact us for useful details and a free quotation.

Working principle of the metal chips briquetting machine

The metal briquette press operates on the principle of compressing metal scraps using high pressure. First, the metal waste, such as steel shavings, aluminum chips, or copper turnings, is collected and prepared for the briquetting process.

The prepared metal waste is then fed into the hopper of the briquette press. Inside the machine, a hydraulic or mechanical system applies tremendous pressure to compress the metal scraps. The force compacts the loose metal particles, binding them together and forming solid briquettes. The briquettes are typically in specific shapes, such as cylindrical or rectangular, depending on the machine’s design.

Metal briquetting machine parameters

| Model | Capacity | Density | Control system |

| SL-315T | 300-500kg/h | 2400kg/m³ | PLC automatic control |

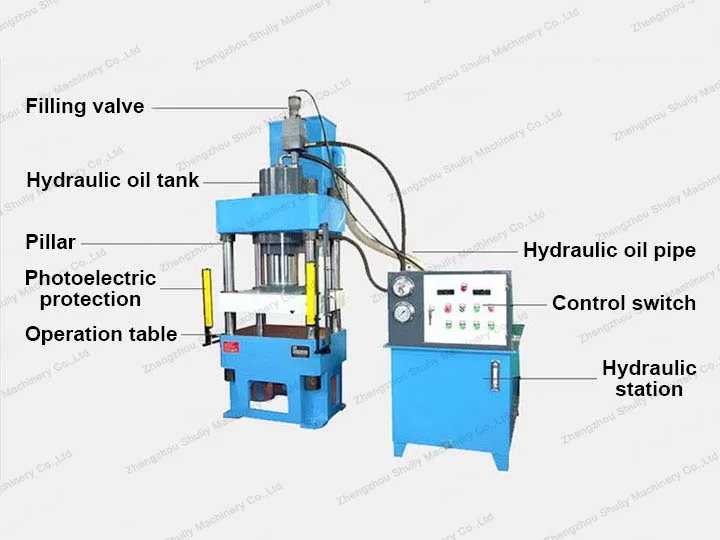

Key parts of the metal scrap briquette machine

A metal briquette press consists of several essential components:

Hopper: The hopper is where the metal waste is loaded before being processed.

Compression System: The compression system, powered by hydraulic or mechanical mechanisms, generates the high pressure needed to compact the metal scraps into briquettes.

Die and Punches: The die and punches determine the final shape and size of the briquettes. They are responsible for shaping the compressed metal waste.

Ejector System: Once the briquettes are formed, an ejector system pushes them out of the press, allowing for continuous production.

What are metal briquettes used for?

Metal briquettes, which are compacted and dense forms of metal waste created using a metal briquette machine, have various uses and applications across different industries. Here are some common uses of metal briquettes:

- Recycling and Smelting: Metal briquettes are often used as a feedstock in metal recycling and smelting processes. They can be melted down and reused to produce new metal products or alloys. By using metal briquettes as a raw material, manufacturers can reduce the reliance on primary metal sources and conserve natural resources.

- Foundry and Casting: Metal briquettes are employed in foundries and casting facilities to achieve precise and controlled metal pouring. They are used as a charge material in furnaces to ensure consistent melting and casting processes. Metal briquettes with specific compositions can be tailored for specific casting requirements, such as achieving desired alloy compositions or controlling impurities.

- Steelmaking: Metal briquettes, particularly those made from iron and steel scraps, are utilized in steelmaking processes. They serve as a supplement or substitute for traditional iron ore and scrap materials, allowing for precise control over the chemical composition and quality of the steel produced. Metal briquettes contribute to cost-effective steel production and help reduce environmental impacts.

- Metal Fabrication: Metal briquettes find application in metal fabrication industries for various purposes. They can be used as a source of raw material for producing metal components, such as sheets, rods, or wires. The compact form of metal briquettes makes them easier to handle, transport, and feed into manufacturing processes, enhancing efficiency and productivity.

- Energy Recovery: Metal briquettes with high calorific value, such as those derived from certain types of metal waste, can be utilized as a fuel source in various industries. They can be used in thermal power plants, cement kilns, or other energy-intensive processes to generate heat and electricity. Metal briquettes offer an alternative energy source while reducing the environmental impact of fossil fuel consumption.

- Export and Trade: Metal briquettes, especially those made from high-quality metal waste, can be exported and traded internationally. They are sought after by manufacturers and recyclers worldwide as a reliable and consistent source of raw material. Exporting metal briquettes contributes to global recycling efforts and fosters a circular economy.

Benefits of metal briquette press

1. Volume Reduction: Metal briquette presses significantly reduce the volume of metal waste, making it easier to handle, store, and transport. This helps save space and reduces logistical costs.

2. Increased Value of Metal Waste: By transforming loose metal scraps into dense briquettes, their value increases. Briquettes are more convenient to sell or recycle and fetch a higher price compared to loose metal waste.

3. Environmental Benefits: Metal briquette presses contribute to environmental sustainability. By compacting metal waste, they reduce the need for landfill space, minimize air pollution from burning metal waste, and promote the recycling of valuable metals.

4. Improved Handling and Storage: Briquettes are easier to handle and stack compared to loose metal waste. They can be stored neatly and efficiently, reducing clutter in workplaces and improving safety.

5. Versatility: Metal briquette presses can process a wide range of metal scraps, including steel, aluminum, copper, brass, and more. This versatility allows for the recycling of various types of metal waste.

6. Cost Savings: By compacting metal waste into briquettes, businesses can save on waste disposal costs, as well as reduce transportation and storage costs associated with metal scraps.

7. Customization: Some metal briquette presses offer the flexibility to adjust the density and size of the briquettes, allowing customization based on specific requirements or customer preferences.

Contact us to start your business!

Shuliy is a leading industrial baler machine supplier. The metal briquette press machine is one of our hot products. Besides, our products including various baling machines like scrap metal baler, vertical baler, horizontal baler, etc. And we provide a complete baling solutions for plastic bottle, crap metal, clothing, tyre, and aluminum cans, etc. If you want to start your metal recycling business or other wastes recycling business, reach out us for a free price list.