Scrap metal baler is a machine used to compress and pack scrap metal into bales for easier transportation and storage. They are commonly used in scrapyards, metal recycling facilities, and manufacturing plants that produce a significant amount of scrap metal.

Shuliy Machinery supplies a series of hydraulic metal balers with durable material and high performance. The press power of the machine can reach up to 400 ton. We can fit all your special requirements with strong capability and powerful research ability. Welcome to contact us for the best quote.

High quality scrap metal baler for sale

Shuliy Machinery offers high-quality scrap metal baler for sale that are designed to meet the needs of scrapyards, recycling facilities, and other metal processing facilities. Their balers are made with durable materials, come in different sizes and capacities, and are equipped with powerful hydraulic systems for efficient and reliable compression of scrap metal into tightly compacted bales. Shuliy also provides excellent customer support and technical assistance, and their prices are competitive, offering great value for the quality of their machines. Their scrap metal balers are designed to improve efficiency, reduce storage space needed, and increase profitability for businesses of all sizes.

What is a scrap metal baler?

A scrap metal baler compresses scrap metal into tightly compacted bales using hydraulic pressure, making it easier to store, transport, and process. It reduces the storage space required for the metal and improves handling and transportation efficiency. It is commonly used in scrapyards, recycling facilities, and other metal processing facilities that handle large volumes of scrap metal.

Features of Shuliy Metal Baler Machine

- Computer control, high automation level, and low failure rate

- Simple structure, smooth operation, easy to install, operate, and maintain

- The hydraulic force ranges from 125 ton to 400 ton, a full range of products to meet your specific needs

- Quality assurance, durable material, long service life

- OEM & ODM service

- Special customized hydraulic system and motor

Scrap metal baler machine parameters

| Equipment model | Pressure(ton) | Press bin size(mm) | Bales size(cm) | Press time(s) | Power(kW) |

| SL-Y81-125 | 125 | 1200*800*500 | 30*30 | 100 | 15 |

| SL-Y81-135 | 135 | 1200*1000*600 | 30*30 | 110 | 18.5 |

| SL-Y81-160 | 160 | 1200*1000*600 | 35*35 | 110 | 18.5 |

| SL-Y81-180 | 180 | 1600*1200*800 | 40*40 | 130 | 22 |

| SL-Y81-200 | 200 | 1600*1200*800 | 50*50 | 140 | 22+15 |

| SL-Y81-250 | 250 | 2000*1750*1000 | 50*50 | 150 | 44 |

| SL-Y81-315 | 315 | 2500*2000*1200 | 60*60 | 160 | 60 |

| SL-Y81-400 | 400 | 3000*2500*1200 | 60*60 | 170 | 90 |

The pressure power of the machine is from 125 ton to 400 ton. And the press time can be as short as 100 seconds. And the power can be up to 90 KW. Besides, we provide strong OEM service to fit all your specific requirements. Welcome to contact us to get your best baler solution.

Application scope of metal scrap bailing machine

The metal scrap baler machine has a wide range of applications. It is suitable to compress scrap steel, aluminum, copper, stainless steel, plastic, carton, etc into metal bail or block. The purpose of using a metal scrap baling machine is to save on transportation costs and minimize raw material loss during smelting.

Scrap metal baler machine working video

What affect the scrap metal baler price?

Scrap metal baler price is not fixed and is affected by lots of factors, including:

1. Size and Capacity: The size and capacity of the baler can significantly impact the price, as larger and higher-capacity balers generally cost more.

2. Features and Automation: Additional features and automation, such as automatic wire tying or computer-controlled systems, can increase the price of a baler.

3. Manufacturer and Brand: Different manufacturers and brands may have different pricing structures based on their reputation, quality, and level of customer support.

4. Market Demand: Market demand and availability of materials used to build scrap metal balers can also impact the price.

5. Condition: The condition of a used baler can significantly affect its price, with newer machines in better condition generally being priced higher.

How does a scrap metal baler machine work?

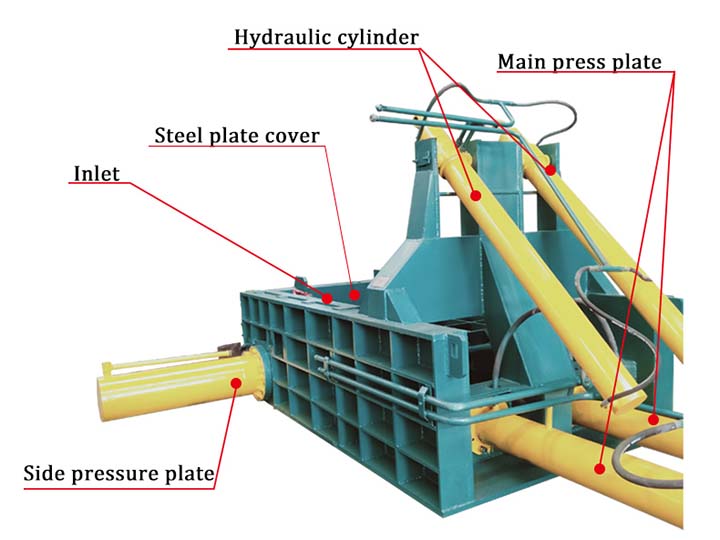

A scrap metal baler machine works by compressing scrap metal into tightly compacted bales using hydraulic pressure. The process typically involves feeding the scrap metal into the machine, which then uses hydraulic power to compress it into a bale. The metal is compressed to high pressure, and the bale is held together with wire or strapping. Once the bale is tied, it is removed from the machine and can be easily transported using a forklift or similar equipment. The scrap metal baler machine comes in different sizes and models depending on the volume of scrap metal that needs to be processed. This process helps to reduce the storage space required for scrap metal and improves efficiency in handling and transportation.

Shuliy Machinery provides excellent scrap metal baler for sale with high quality, competitive price, and intimate service. Apart from metal bailing press machine, there are various vertical baler machine and horizontal baler machine for cardboard, paper, clothing, plastic bottle, cotton, aluminum can, etc. Welcome to reach out to us for useful machine details and a free price list.